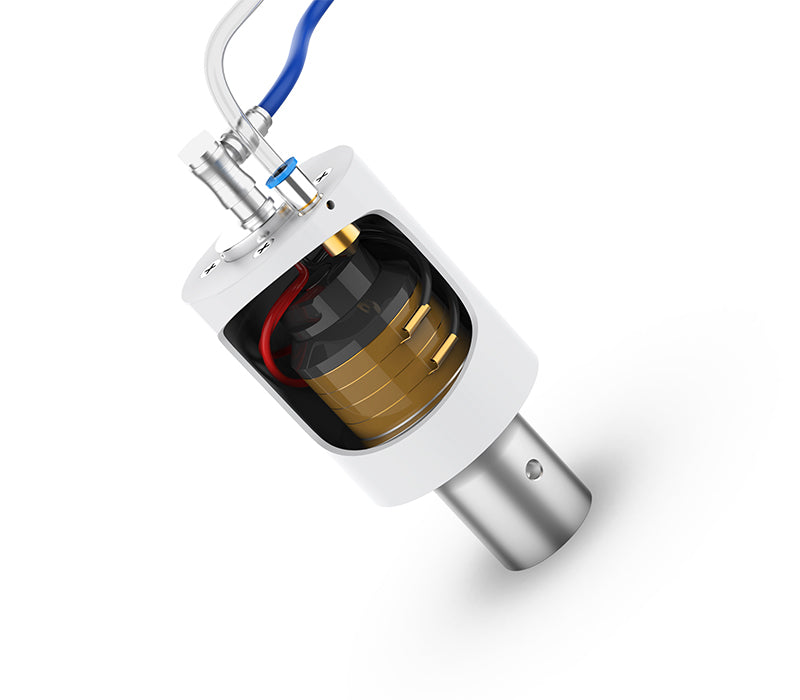

To adapt to various environments and applications, HS SONIC mainly provides transducers of two structural types

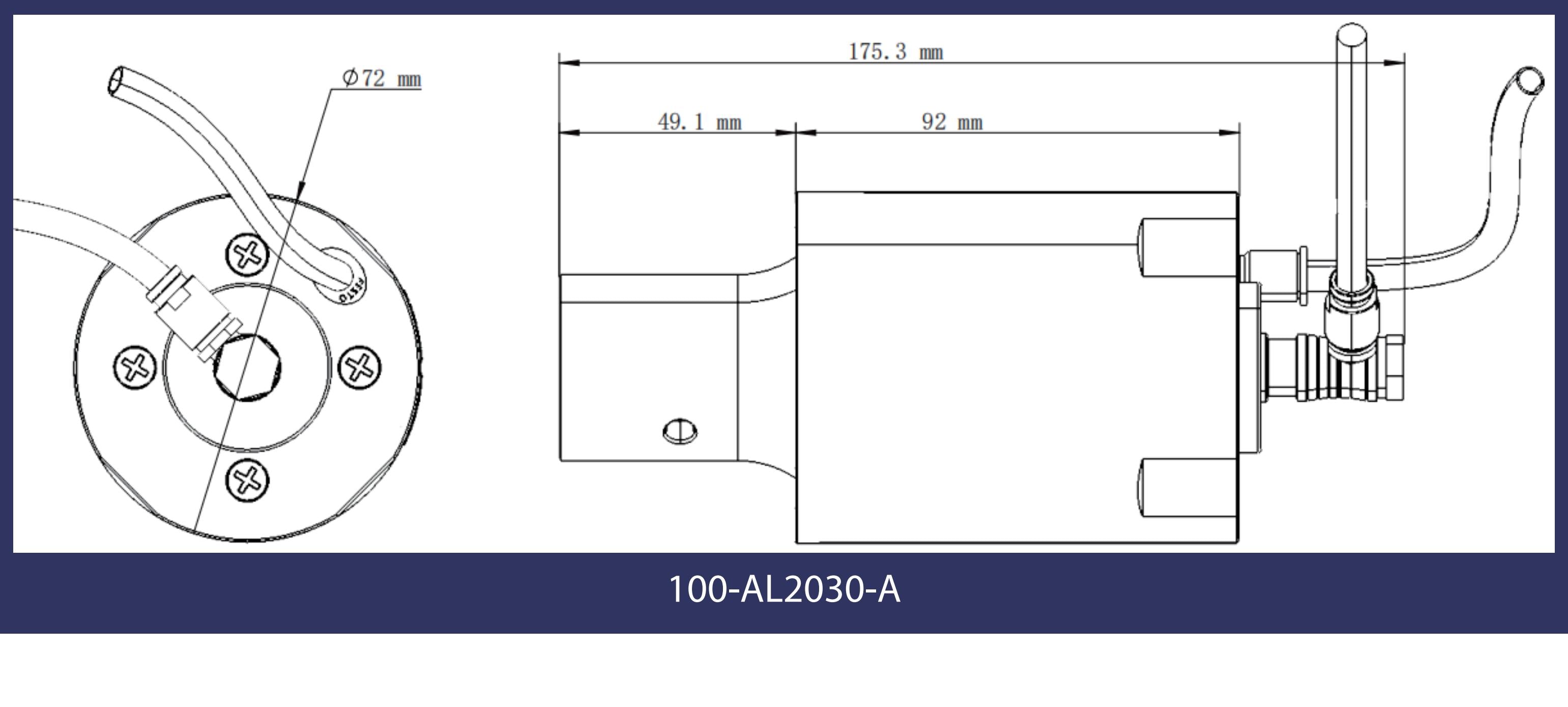

Aluminum alloy transducer

≤4000W

The heat dissipation method is achieved through gas supply, providing a solution for most low-power general-purpose applications

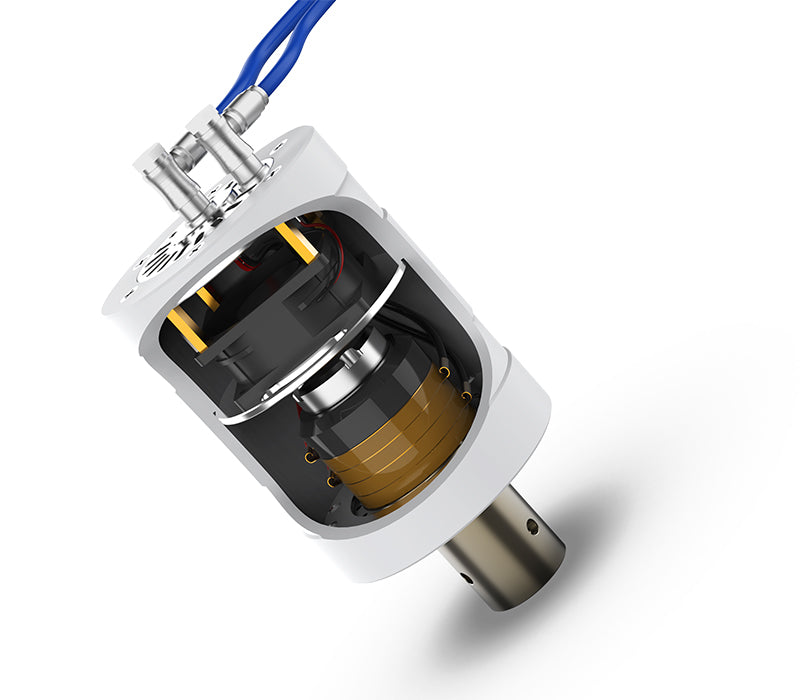

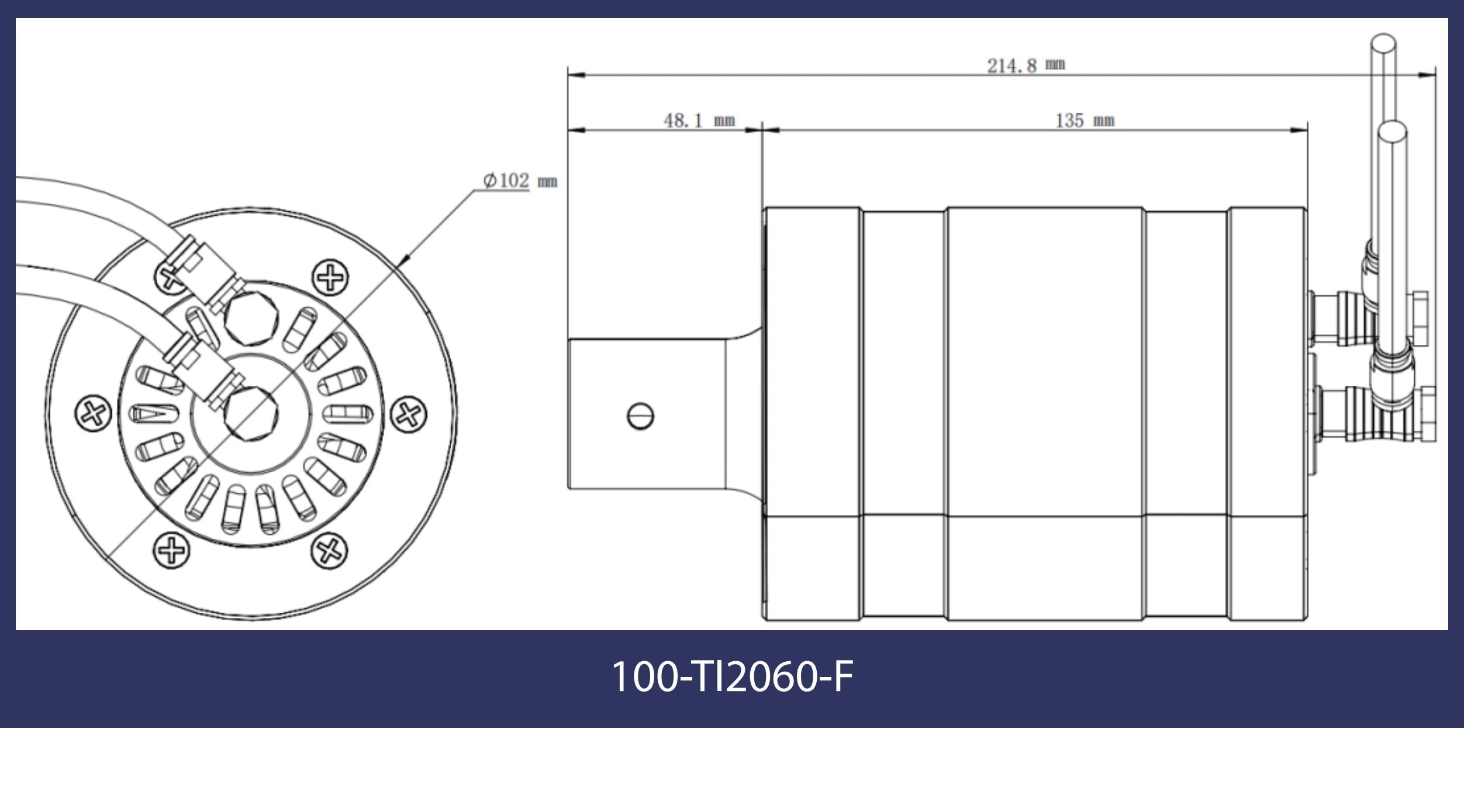

Titanium alloy transducer

≤6000W

The heat dissipation method is carried out by a super-strong silent fan, providing a stable welding solution for high-power special applications

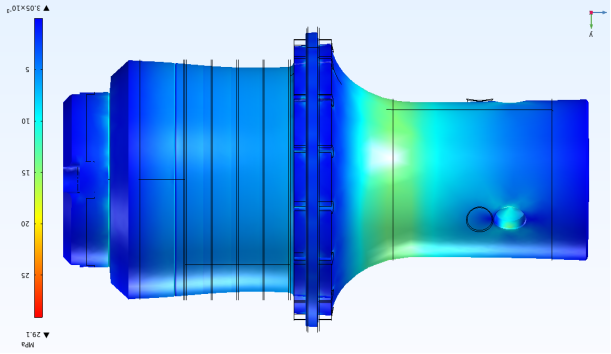

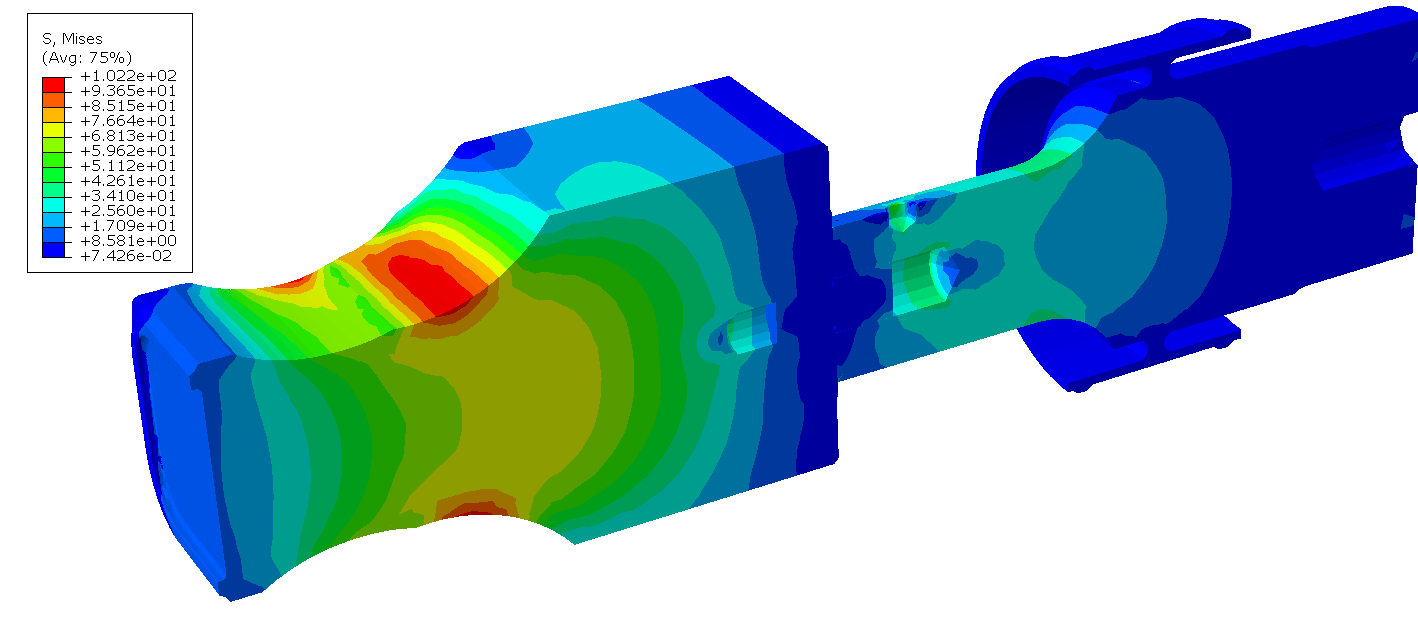

Structural strength design

The service life exceeds one million times

HS SONIC adopts multi-physics field coupling simulation technology to scientifically design the transducer structure, amplitude transformer and welding head, effectively resisting high-frequency vibration and shock, ensuring that the transducer service life exceeds one million times, and guaranteeing the efficient and stable ultrasonic welding.

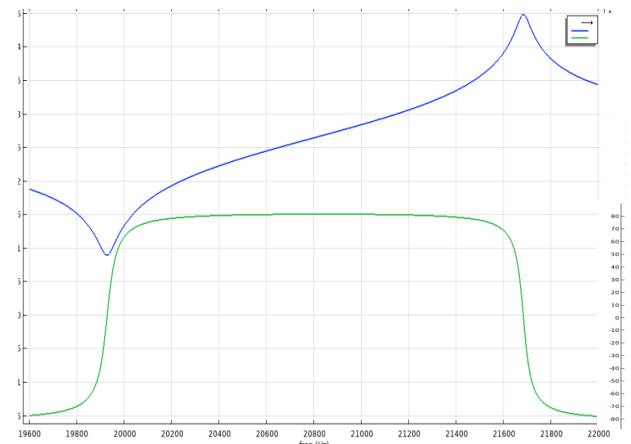

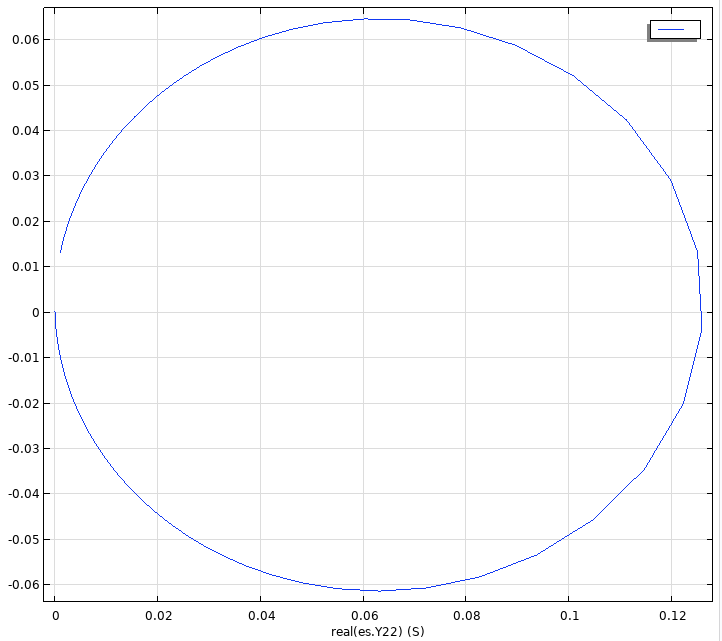

Electrical characteristic design

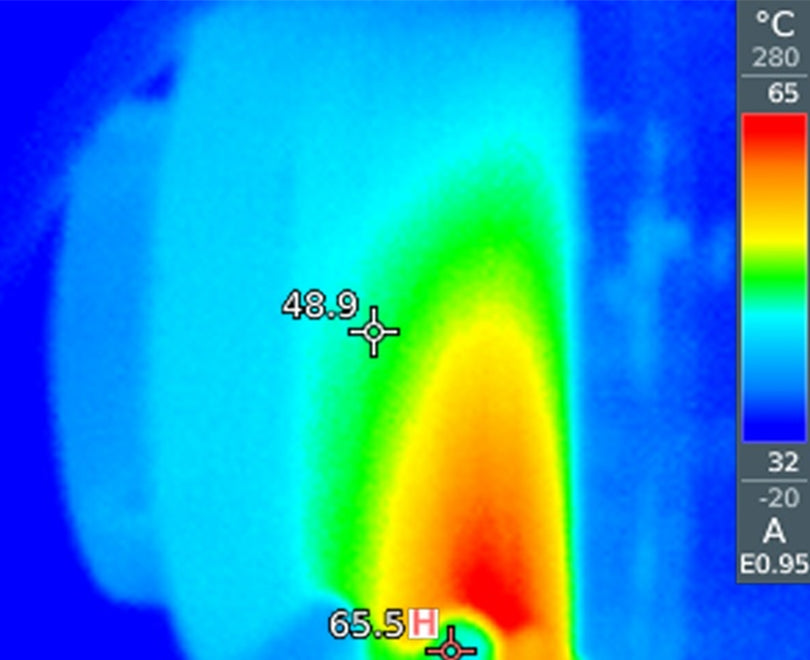

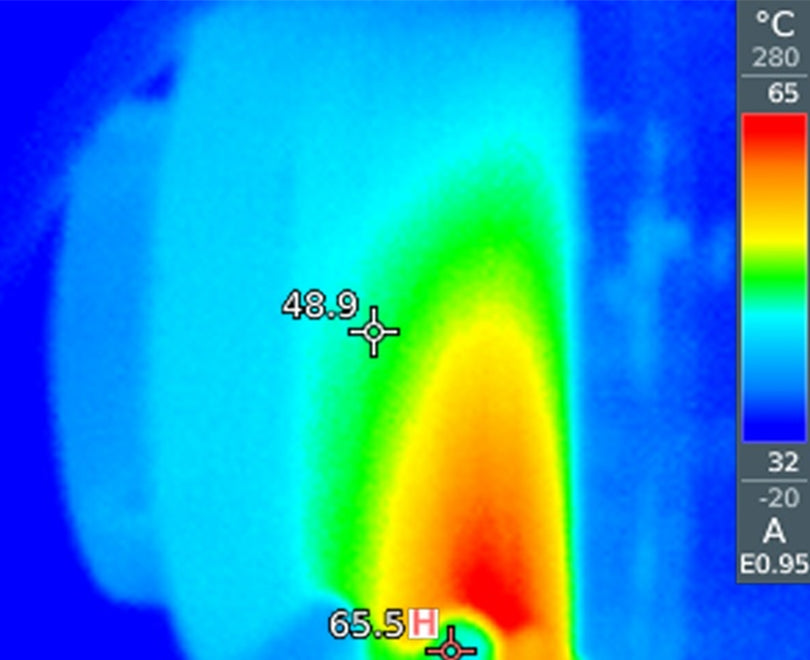

Extremely high thermal stability

When the HSSONIC transducer operates at a continuous peak power of 5000W, the maximum temperature of the transducer remains stable at 65℃, limiting the impact of temperature on the acoustic system and ensuring the consistency of the welded products.

Our signature product.

Multiple models are available